Growing responsibility needs continuous investment

In an era when the industrial world is becoming ever-larger, there is a growing responsibility on equipment suppliers to make sure the market has everything it requires to function safely, reliably, efficiently and cost effectively.

With this in mind, JD Neuhaus has always had a policy of continuous investment in its range of hoists and cranes.

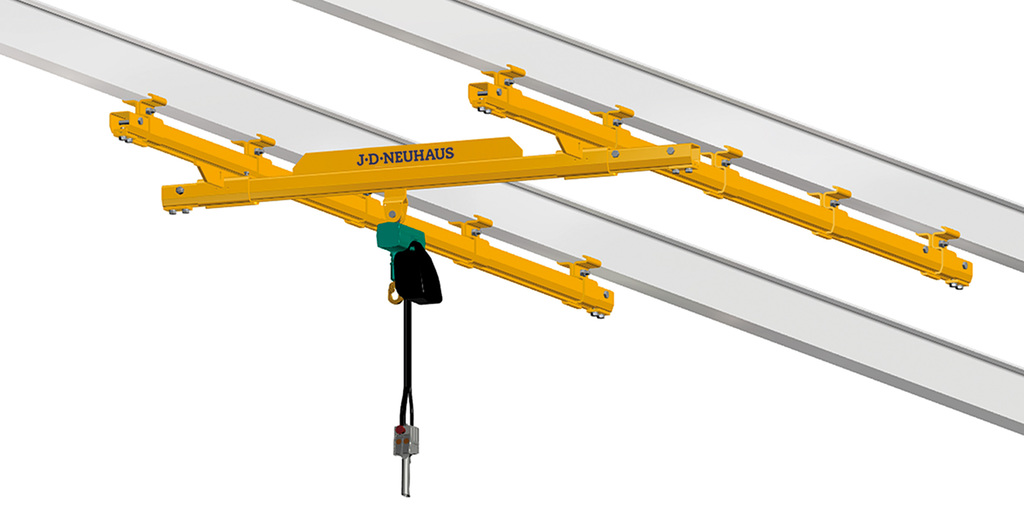

The company says: “Our range is broad and feature-rich, ensuring virtually every type of general application can be served. Products available include pneumatic cranes, C-rail/light crane systems, pneumatic hoists (Profi, Mini and M ranges), manipulators, trolleys (including low headroom versions), big bag handling hoists and monorail hoists.”

The latest products have been engineered to offer extended service life, simple operation and ecological compatibility, without any compromise to safety or performance, says the company. Among the latest innovations is the JDN-RC (Remote Control), which comprises a transmitter and receiver, and is suited for new and retrofit applications.

Of course, due to the wide-ranging demands of industrial applications in which hoists and cranes are expected to perform, all JDN products are engineered for extremes. Typical applications include aircraft construction, general assembly lines, auto plants, dairies, electroplating lines, foundries, paint shops, steelworks, power plants, refineries, sawmills, shipyards and tempering plants, as well as a host of uses in the chemical, cement, food, furniture, glassmaking, paper and textile industries, to list but a few.